UPAA Blog 2022-23 #4 - 10/13/22 (photos and text by Jaren Wilkey)

Jaren Wilkey is director of BYU photo. His Sports Features and Illustrations category image "Royal Icing" was voted best in show in the September 2022 Monthly Image Competition. The MIC Q&A is a monthly feature on the UPAA blog to learn more about the thought and craft behind the UPAA's contest-winning images. -Ed.

************

1. Quick tech stuff—camera model, focal length, exposure data, lighting used (if any):

•Canon R3

•RF 70-200 at 86mm

•1/2500 Sec, f3.5

•3 Arri ST1 studio lights, Tungsten White Balance

2. Was this photo assigned or enterprised? What was your plan/vision prior to the shoot?

It used to be that football uniforms were, well, kind of uniform. You had one combination for home games and another one for road games. Nowadays we have a unique uniform combination for each and every game, and every Monday we reveal the uniform to be worn that week. (see this tweet for an example)

The uniform reveal after design work.

Our Athletic Marketing team wanted to create new photos and videos for the weekly uniform reveal. We’ve been brainstorming unique ideas and concepts for all 12 combos, which has been a great opportunity to create photos that are very different from the studio cutouts we normally produce. This year we were also going to introduce a new royal helmet with a chrome finish, and I really wanted to do something special for that shoot.

For the longest time I’ve wanted to create a photo of an athlete running through a sheet of ice. I thought it would be an amazing visual that would stand out, plus we could record it with a high speed camera to create slo-mo video for social media posts. If you want to make a splash you need to go big. I pitched the idea to the marketing team and they loved it, but now I had to figure out how to make it happen.

3. Any unique logistics in making the photo? (The UPAA blog realizes this is arguably the most superfluous question ever asked in a MIC Q&A, but, hey, gotta stick with the template...)

I looked into freezing sheets of ice in one of the large culinary freezers on campus, and then transporting them to our studio in a refrigerated truck, but ice is just so difficult to work with. To get a sheet of ice big enough to run through would have required ice so thick that it wouldn’t have been safe to use.

The chefs at the culinary center suggested I try sugar glass; it would be a lot easier to make and it was far safer to work with. Sugar glass is basically sugar heated up to a liquid and cooled in a form until it solidifies into brittle transparent sheets that look and break like glass. The best part is that when it breaks the edges are not sharp, which is why sugar glass has been used by stuntmen in Hollywood for decades.

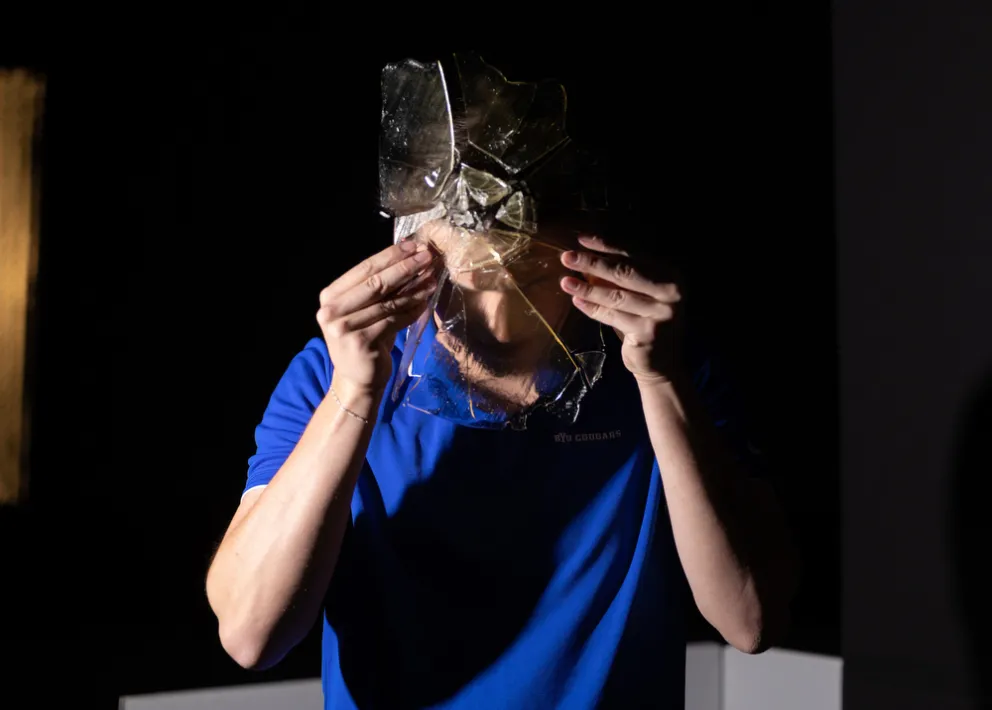

Being a student photographer at BYU isn't all it's...cracked up...to be (!!).

After some extensive googling I found a recipe and I went home and made a small batch of the sugar glass and it surprised me how brittle it was. The next day I brought it into the studio so that we could test it out on one of my students. Matt broke the slab with his head and we got really excited because it looked amazing. The real challenge was to see if I could make a sheet big enough for a large football player to run through. I had originally wanted to make a piece the size of a door so that you could see their whole body crashing through it, but I quickly found out how unrealistic that was. There was no way I could pour a sheet that big into a mold and transport it to the studio without it breaking prematurely.

Chef Jaren gets to work.

For the mold I bought a large plastic tray that is made for the bottom of a pet carrier, but when I poured a test sheet it warped because of the heat. I also looked at metal water pans that are placed underneath washing machines, but I would have had to join several pieces together to make the sheet big enough. I finally went to home depot and bought several sheets of 4’x3’ sheet metal and I just bent the corners up to make a tray. In my research I learned that the best thing to do would be to put parchment paper in the tray so it would release the sugar glass without breaking it. I also bought sheets of plywood to put underneath the forms so that we could pick them up and drive them to the studio. This also protected my new granite counters from the heat of the molten sugar, which protected my marriage.

It really does look like 'Breaking Bad,' doesn't it?

The recipe for sugar glass is pretty simple, I just had to scale it up. The recipe is:

5 cups of water

7.5 cups of corn syrup

20 cups of granulated sugar

The corn syrup keeps the sugar from crystallizing as it cools and the water just makes it easier to mix the sugars together, and it burns off during the cooking process. All you need to do is mix the three ingredients (I split it into 2 pots) and heat them up to between 280-300 degrees F while stirring them every few minutes. This is called the hard crack stage, a candy making term that means when the liquid sugar cools it will be brittle. I made a whole batch that I pulled off too early and it turned out like hard taffy, so I had to toss it and start over. It took about an hour to heat up to the hard crack stage, which gave me plenty of time to think about how my life had become the Disney version of “Breaking Bad”.

It’s a good idea to wear gloves and safety goggles because at this stage you are working with molten sugar and I burned one of my fingers with the sugar lava. Once it hit 280 I poured it into the form and waited another hour for it to cool, and it kicked off a lot of heat. The final product turned out amazing, it just looked like a piece of slightly yellow glass. My boys helped me load it into the back of our minivan and we drove it to the studio.

Setting it up in the frame.

The next challenge was to find a way to hold the glass vertically in place. I originally thought of buying a door frame and adding a small shelf for the sugar glass to sit on, but it would have been a bit narrow for a large athlete with shoulder pads to run through. My dad is a general contractor and I worked construction before I became a photographer, so I just built my own frame. It was just a simple rectangle made from 2 x 4s with some bracing on one side to keep it upright. I attached a few small pieces of wood on one side so the glass could just sit on and we planned to clamp the glass to the frame. Once we built the thing it looked more like a guillotine than a door frame, so that’s what we called it. We picked up the plywood with the form on top of it and slowly rotated it vertically onto the frame. Once the glass was sitting up on its own, we pulled away the plywood, the sheet metal frame and then we peeled off the parchment paper.

There was no way that I would ask an athlete to run through sugar glass unless I knew that it was completely safe, so I decided that I would be the test dummy. For the full scale test I put on some safety glasses and a baseball helmet, because it was the only helmet I had on hand. We also set up a few cameras to capture photos and video of the test so that we could get a good idea of the adjustments we needed to make for the real photo shoot.

Other duties as assigned: Crash test dummy!

When you are standing in front of a large piece of sugar glass with the intention of crashing through it your brain tells you “you’re an idiot, this is going to hurt”, but you just have to force yourself to move. When I ran into the glass, it gave some resistance on my shoulder but then it just exploded. The best way that I can describe it is like running through a piece of wet drywall.

When we looked at the video clip it looked amazing. I loved how the sugar glass broke up into thousands of small fragments and went everywhere. This is when I got really excited to get the athletes in the studio. The problem was, we were still waiting on the new Nike uniforms to be shipped to the team, so we were on hold until the swoosh delivered.

Since I had a few weeks before the shoot, I looked into using isomalt instead of regular sugar. Isomalt is a refined sugar created specifically for making sugar glass. It is a lot easier to work with and you don’t need to add any corn syrup to it so it solidifies clearer than regular sugar glass. The drawback is that it is more expensive than regular sugar and a bit more brittle. I tested out a small batch and decided to order enough to make 2 sheets of Isomalt glass to go along with 2 sheets of regular sugar glass. That way I could photograph 2 athletes with both types of sugar.

The day before the shoot, I spent about 8 hours cooking and pouring the 4 sheets and transporting them to the studio. We learned that If we poured the molds and then quickly took them to the car, they were still pliable and less likely to break during the trip. I also purchased a small iron so I could patch any cracks in the glass before the photo shoot.

From the beginning of the planning we knew that we were going to capture both photos and videos on set. We decided to shoot on our black background so that the glass would stand out. On the day of the shoot we rented a Phantom camera to capture high speed video at 5000 frames per second. High speed cameras need a lot of light so we lit our set with 3 Arri ST1 studio lights. One was placed directly above the helmet so that it would light our logo and the other 2 were placed behind the runway on each corner. Those rim lights would highlight the edges of the sugar glass while they were flying through the air. Whenever you shoot something transparent like water or glass use backlighting to make it stand out from the background.

A frame from a behind-the-scenes video shows the setup and the lighting.

In addition to the Phantom we were excited to try out the Canon R3’s new high speed video feature. A recent firmware update allowed us to capture 240 fps at 1080P. We placed the Phantom and the R3 perpendicular to the runway so that the athlete would run through the glass and into the frame, revealing the helmet. We also had an R3 placed at the end of the runway so the athletes would run directly towards it.

To capture stills I was able to use another new feature of the Canon R3, which is called Custom High-speed Continuous Mode. It allows you to capture a burst of 50 RAW images at any frame rate between 30-195 frames per second. This is a pretty incredible feature, one that was perfect for capturing the sequence of shattering glass. I chose to capture a burst of 50 shots at 100 fps, which gave me a half second burst.

When the athletes arrived on set we had them do several run-throughs without the glass so that they could get their movements down and we could test our cameras and make any adjustments. We also prefocused every camera on where the helmet would be after it passed through the glass plate. Rather than have my still camera on a tripod I decided to shoot it handheld so I could pan it with the athlete as he ran through the glass. Panning the shot helps the moving subject to be sharper than it would be by placing the camera on a tripod. It also helped me trigger the burst at the right moment to capture the maximum amount of exploding glass.

Once we felt like everything was ready, we wheeled in a table with the first sheet of sugar glass and slowly lifted it into place. It was unnerving to hear the glass cracking and not be able to do anything about it, but we finally got it up on the stand. Surprisingly it was mostly in one piece. Everybody ran to their station and started recording. Miles Davis is one of our running backs and he was the first one to run through the glass. He hit it perfectly and the explosion of sugar was shocking. Sugar glass went everywhere and all of our team exhaled in relief because it actually worked. We immediately saw the images transfer onto the iPad and we knew we had something special. We also looked at the high speed footage and it blew us away. I couldn’t wait to do it again.

The sweet smell of success--literally! "The studio still smells like a Willa Wonka factory," said Jaren.

The first 3 pieces of sugar glass worked great, but the 4th one, which was made from Isomalt, had a big crack in it even before we tried to place it on the stand. It broke into several large pieces so we just held the pieces in place with our hands so the athlete could run through them. Thankfully we already had plenty of great shots so it didn’t hurt us in the long run.

4. Did your vision before you made the photo come through in the final product? What (if anything) would you do differently if you could re-shoot this today?

After all that work it was a huge relief to be done. I’m thrilled with how it turned out and with everybody’s reaction to the photos and the video. The most challenging part was making the sugar glass, it was time consuming and hard to move. Somebody asked me how much it would cost to pay somebody to make it for us. Hollywood now uses plastic resin instead of sugar glass. But to make 1 sheet the size I needed it, it would cost almost $600 dollars. I was able to make all 5 sheets and the molds for around $500.

A mess, but worth it!

In case you are wondering, It was a nightmare to clean up. I put down sheets of plastic to catch as many of the shards of sugar glass that I could, but It didn’t really help. The stuff went everywhere and got into everything. I had to mop the studio floor 3 times to get them clean and then repaint the floor because walking on the sugar glass destroyed the black paint. It's been a whole month and the studio still smells like Willy Wonka factory. To this day, I still find sugar glass hidden like easter eggs in random places like softboxes and sandbags.

5. What do you do to keep yourself motivated and interested in your work?

I’ve never seen somebody do a uniform reveal in this way and now I know why. This is the kind of project that I love to do because it is so challenging. Solving visual problems is at the heart of my motivation and I’m fortunate enough to work with people that trust me when I have a crazy idea that might just work.

************

"I thought breaking glass would be easy. Turns out it's a real pane." Thanks for reading the UPAA Blog. Send your comments & suggestions to editor Matt Cashore, mcashore@nd.edu. Heard of this new thing called Instagram? It's the latest sensation sweeping the nation and UPAA is on it! Give 'em a follow.